Sorting

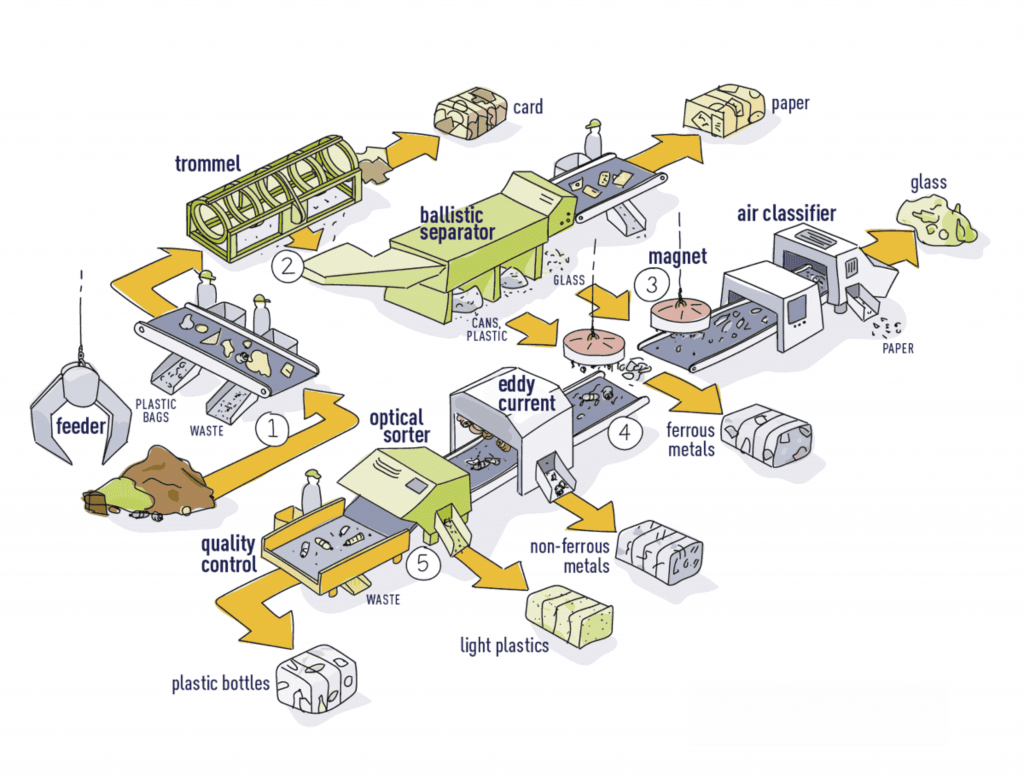

After plastics are collected and transported to a recycling facility, the first step is sorting. Manually sorting of the plastics according to their particular resin content. This is important because different types of plastics must be processed in different ways and some recycling facilities are only capable of recycling certain types of plastic.

Washing

After a sorting, the plastic waste needs to be washed properly to remove impurities such as labels, adhesives or even food residue. Non-plastic waste cannot be recycled and can cause the final product to have poor structural integrity.

Resizing – Shredding

Resizing consists of shredding or granulating the plastic waste into small particles. This increases the surface area of the plastic, making it easier to process, reshape, and transport if needed.

Extruding

The dry flakes are melted down and extruded for with extruder. They can be melted down and extruded into a new shape or they are extruded processed into granules.

Making of pellets

After the melting process, the plastic pieces are then compressed into tiny pellets known as nurdles. Compounding is when the small particles are smashed and melted together into plastic pellets.

Throughout this process, the plastic may be moved to our or different plants that specialize in different steps of the process.